A suitable approach for repairing concrete cracks is selected according to an assessment of the source of the fracture in the structure. Once the source is identified, the crack type can be determined. Once this is done, the appropriate technique can be picked. When this drying shrinkage is the cause of the cracking, the cracks will likely cease to develop after some time. But if the fissures are the result of an ongoing foundation settlement, fixing the problem will be futile until the foundation settles again. To select the best method for the same resin-expert.com Guide will help you out for the same.

Epoxy Injection Procedure

Cracks no more than 0.002 inches wide can be treated using an epoxy injection procedure. The procedure normally involves using many ports of various sizes and tight spacing around cracks, which are then sealed with epoxy on the exposed surface, which is then injected under pressure. A polymer gel (known as “epoxy”) will be effectively employed in the restoration of concrete structures, such as buildings, bridges, dams, and retaining walls. Unless the root cause of the cracking has been treated, the cracking will most likely repeat around the initial fracture.

The cracks cannot be eliminated, therefore the two alternatives are to let them spread or fill them up. To fix the crack, either a joint should be created first to accept the movement, or a joint should be sealed first to accept the movement, and then an adhesive should be injected. When small holes have been made in the dam to prevent the loss of water, they can be filled with epoxy resin mixed with specialized compounds that will harden when wet. However, any pollutant that was in the crack before filling would diminish the efficiency of the epoxy.

Adhesives with a low modulus, which will help prevent major movement of the concrete structure, are not appropriate for usage in a crack. Although a flexible glue has a much lower effective modulus of elasticity than a stiff adhesive, it has nearly the same effective modulus of elasticity because of the very thin layer of material, plus the concrete on all sides of the crack offers a lot of lateral restraint. This injection method is more difficult to learn and practice because of the necessity of great precision and the fact that application in an unfavorable environment can be difficult.

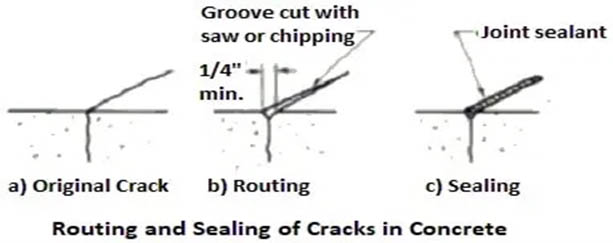

Routing and Sealing of Cracks Procedure

Routing and sealing of cracks can be employed in situations when a remedial repair is required, as well as in situations where structural restoration is not essential. The approach described above entails increasing the fracture on the visible face and then capping and sealing it with a suitable joint sealant.

It is widely employed in crack therapy, and it is very simple to practice when compared to the other practices and the time it takes to become proficient with epoxy injection. This approach is effective on horizontal surfaces, such as floors and pavements, which have only small deviations from being perfectly level. This is a standard and reliable utilization of waterproofing, and it can be used to seal the cracks on the concrete surface when water accumulates, or when hydrostatic pressure is imposed.

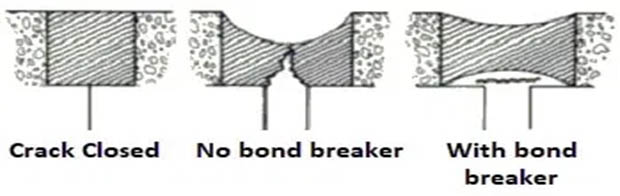

This treatment will prevent moisture from getting to the reinforcing steel or from passing through the concrete, and as a result, surface stains or other issues can be prevented. The method consists of making a groove at the surface that varies in-depth, and it normally ranges from 1/4 of an inch to an inch (6 to 25 mm). Once the groove has been cleaned, it is washed with either air blasting, sandblasting, or water blasting, and then left it to dry. A sealant is put into the dried grooves and allowed to cure. For the sealant to fill the hole, it will have to adapt to the contour of the hole. To reduce the risk of bond breakage, a bond breaker is placed toward the bottom of the groove so that the sealant is not disproportionately pressured towards the bottom.

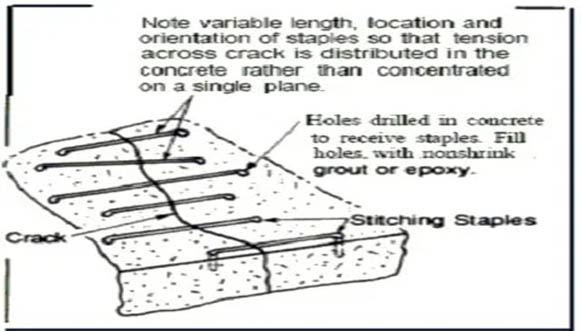

Concrete Crack Repair by Stitching

Cracks in concrete can be repaired using a stitch-and-seal technique. The stitch that is depicted in the figure below stitches two metal units on both sides of the crack, after which the cracks are grouted using a U-shaped metal structure with short legs. The tensile strength can be regained if the seams are sewn to reinforce the edges of significant cracks. Before drilling is done, holes are first drilled on both sides of the fracture. The holes are subsequently cleaned and prepped, after which they are used. Once the legs are firmly planted into their respective holes, they are next capped with permanent-style spikes or a pair of wooden ones. Depending on the grout or bonding process employed, these holes are then filled with epoxy resin or grout of a non-shrink nature.

Moisture-resistant dry packaging method

The dry packing method involves simply applying a low water content mortar in hand placement followed by tamping or ramming the mortar into position, which forces the mortar to get into intimate contact with the existing concrete. The low water-cement ratio of the material means there is very little shrinking, and the patch stays tight and retains high quality concerning strength, durability, and water tightness. Filling narrow spaces that have been cut for the restoration of latent cracks can be done using a dry pack. The usage of a dry pack is not recommended for filling or healing active cracks.

Preventative measures should always be taken when using dry packing to repair a crack before it has the opportunity to get wider. To ensure that the slot is just slightly wider than the surface, the undercut should be at least half a millimeter deep. To help prevent shrinking while in place, the mortar should be mixed for half an hour, following which it should be remixed before use. The mortar should be spread in thin layers, approximately 3/8 inches (10 mm) thick. When compacting each layer, be sure to use a blunt stick or hammer on the surface to aid with adhesion, and use a wooden or plastic dowel or hammer on the bottom to aid with better bonding. Either water or a curing solution should be used to finish the repair.

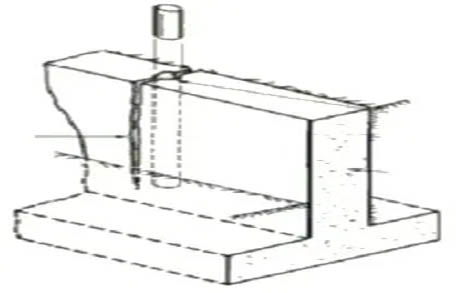

Drilling and Plugging Method

To fill a crack with drilling and plugging, start with drilling down the length of the crack and finish by grouting the hole to complete the job. Cracks which run in straight lines and which are accessible on one end are ideal for this procedure. Vertical fissures in retaining walls are commonly repaired using this approach. A hole, centered on and following the crack, should be drilled. To ensure transverse motions don’t occur, use the grout key.

To decrease significant leakage as well as loss of soil from behind a leaky wall, the key can be used. Drilled holes should be filled with a low-modulus resilient material rather than grout if water tightness is required but structural load transmission is not.