PAT testing is a vital process for schools that can save them a small fortune. A common misconception is that it is expensive to test all appliances in a school, but with the help of experts, this can be done more quickly than you might think.

Dedicated PAT testers can be purchased in a variety of types and levels of complexity. Simple pass/fail models are available for primary testing purposes, while more sophisticated options can provide reports and barcode labels.

1. High turnover of students and staff

The high turnover of students and staff is not just a problem for schools that must hire replacements; it also has long-term impacts on student achievement. High turnover rates make it challenging to develop solid and stable relationships among teachers, and they can damage a school’s ability to teach and support students effectively over time.

Moreover, the constant churn of instructors leads to staff shortages in specific academic departments. This can result in fewer course offerings and a longer time to degree for students. It is also incredibly problematic for schools that serve low-income students and students of color, as they are more likely to have teacher shortages (Olson et al., 2018).

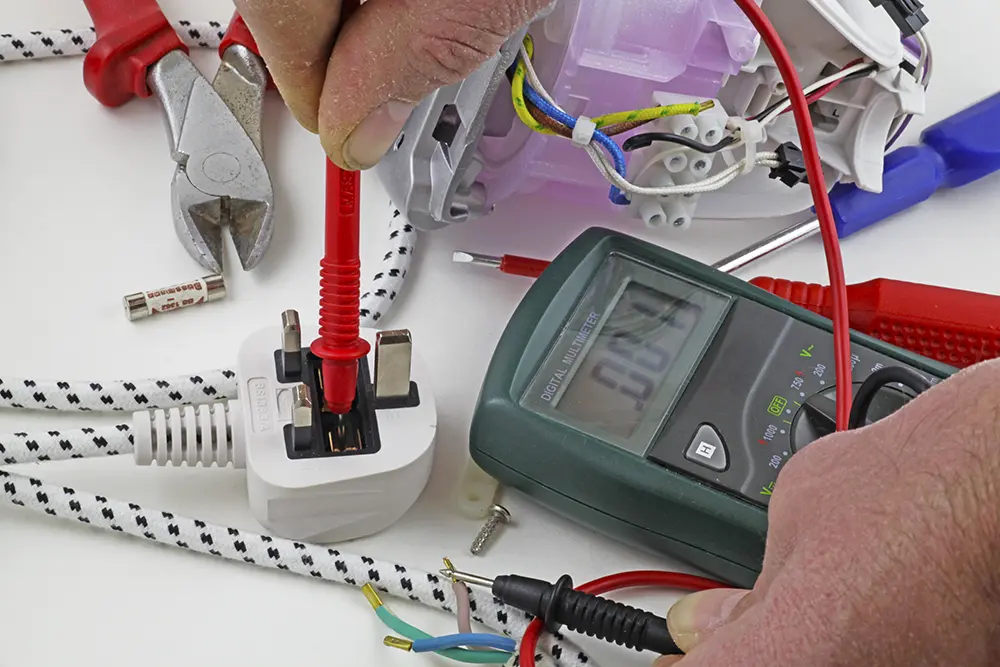

PAT testing is needed for schools, and it must be carried out on all electrical equipment in schools to ensure safety. Fortunately, professional companies can carry out this work without disrupting your school’s daily operations. These experts will perform visual inspections and use specialized equipment to test the wiring of detachable primary cords and plugs. They can then create an enumerated report that details all the devices your school has in place.

2. High risk of equipment failure

Most schools are considered to be high-risk environments for electrical equipment failure. This is because they have a wide variety of electrical items and many staff who may be using them at any time. This also applies to rental properties such as offices and residential dwellings.

Dedicated PAT testers are available in a range of types and levels of complexity. The simplest ones provide a simple pass/fail result and are aimed at in-house testers who do not need to interpret complex results. More advanced models include additional tests such as checking the wiring of detachable mains leads and touch current testing.

A formal visual inspection involves disconnecting the appliance from its power source and opening the plug to inspect the wires, connections, fuse, and cable grip for signs of damage or excessive wear. This should be done by a trained member of staff who is familiar with the risks associated with using electrical equipment and can identify dangers that a user check would miss.

3. High risk of damage to students and staff

While some schools may carry out PAT testing in-house rather than outsourcing it, it is essential to remember that the Health and Safety at Work Act 1974 requires all electrical equipment to be maintained. This includes PAT testing, and not carrying out this process could land a school in legal trouble, with potentially hefty fines.

Performing PAT tests on all portable appliances is essential to reduce the risk of electrical fires. In the UK, over a third of all accidental fires in the workplace are caused by electrical faults, which is often due to poorly maintained or used equipment.

PAT test results provide a valuable snapshot of children’s abilities. They can pinpoint definite strengths and weaknesses and help teachers understand their students’ educational progress. These tests also show the impact of individual differences on learning. For example, a study showed that PAT test scores in Year 3 predict core skills results in Year 12 by a significant proportion.

4. High risk of liability

In the United Kingdom, we have very high levels of workplace safety thanks to effective legislation that requires businesses of all sizes to take precautions to keep their customers and employees safe. PAT testing is a crucial part of this, as it helps ensure that the electrical equipment in a building is safe for everyone who uses it.

When an electrical appliance shows signs of abrasions on its body or has visible damage to the wiring, this is often a sign that it requires a PAT test. This is because abrasions and damage to the wiring can cause electrical faults, which could lead to people getting hurt or equipment failing.

In addition to this, some types of appliances need to be tested more frequently than others. For example, construction sites and hotels require their electrical equipment to undergo a PAT test more frequently than offices and shops.